Los géneros de punto son parte integral de la industria de la moda moderna, reconocida por su combinación de moda y comodidad. Comprender los métodos de fabricación detrás de las prendas de punto puede influir en las elecciones de diseño y la eficiencia de la producción. Este artículo analiza los dos métodos principales de fabricación de prendas de punto: completamente confeccionado y cortado y cosido. Analizaremos sus procedimientos, beneficios y efectos, los cuales te brindarán información que te ayudará en el proceso de toma de decisiones para tu marca de moda o proyecto de diseño.

I. ¿Qué son las prendas de punto totalmente de moda?

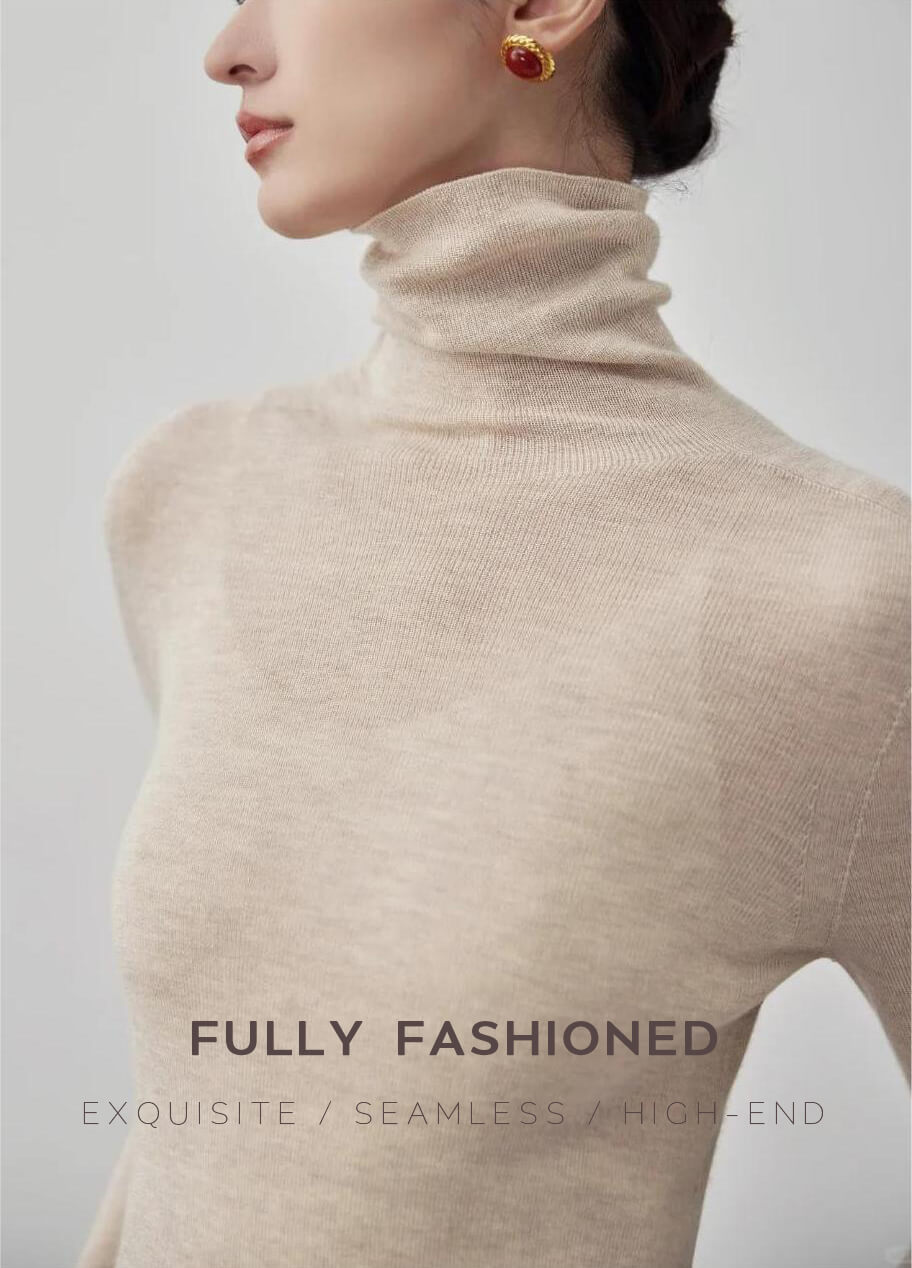

Las prendas de punto totalmente confeccionadas son un método complejo que implica confeccionar prendas utilizando máquinas que tejen. Otros métodos de confección de ropa implican primero cortar y luego coser telas preformadas, pero las prendas de punto completamente confeccionadas eliminan muchos de estos pasos intermedios. Este método facilita un moldeado preciso y componentes de diseño específicos que se incrustarán en la tela durante el proceso de fabricación.

1. Personajes principales:

(1)Conformación directa: La prenda está diseñada para ser exacta, incluidos todos los aspectos de la forma, como cuellos, costuras y nervaduras.

(2)Desperdicio mínimo: Al acoplarse directamente al diseño final, este método reduce significativamente la cantidad de desperdicio de tela en comparación con los métodos tradicionales.

(3) Scalidad superior: Las prendas resultantes de este proceso tienen un diseño sin costuras y suelen ser más cómodas debido al control preciso del procedimiento de tejido.

2. Proceso de fabricación

El proceso completo de confección de prendas de punto implica varios pasos críticos que contribuyen a la calidad de la prenda:

(1)Selector de hilo:

El procedimiento comienza con la elección de hilos que sean de alta calidad y apropiados para tejer. El tipo de hilo afecta la textura, consistencia y apariencia de la prenda terminada.

(2)Tejer:

Para crear los componentes de la prenda se emplean máquinas de tejer especializadas, como máquinas de tejer planas o circulares que tejen. Estas máquinas toman la ruta directa hacia el diseño final, incluidas características como puños, cuellos y componentes de diseño.

(3)Conformación:

Durante el proceso de tejido se emplean varios puntos. Estos puntos, como los lisos y los elásticos, incluyen técnicas para crear formas corporales y componentes estructurales.

(4)Acabado:

Después de tejer, las prendas se someterán a procesos adicionales como planchado, lavado y recorte que garantizarán que cumplan con los estándares de calidad necesarios para su uso.

3. Beneficios de las prendas de punto a la moda

(1)Eficiencia y Reducción de Desperdicios:

Los géneros de punto de moda se asocian con su efectividad. Dado que las prendas se cosen directamente con la forma deseada, este método reduce el desperdicio de tela y disminuye el número de pasos de fabricación.

(2) Describa la precisión del diseño:

La capacidad de incorporar diseños complejos y cambios de forma exactos durante el proceso de tejido permite prendas altamente específicas y precisas.

(3) Implicaciones de costos:

A pesar del gasto inicial asociado con la confección de prendas de punto de moda, el ahorro a largo plazo de materiales y mano de obra la convierte en una opción eficaz para producir productos de alta calidad y con bajo desperdicio.

Las prendas de punto decoradas a la moda se emplean principalmente en moda de alta gama y ropa personalizada, donde la exactitud y la calidad son primordiales. Marcas asociadas con el lujo y el diseño detallado, como Loro Piana y Brunello Cucinelli, normalmente utilizan este método. Loro Piana aprovecha los métodos de moda para crear prendas superiores y meticulosamente diseñadas, mientras que Brunello Cucinelli emplea este método para garantizar un ajuste superior y un acabado lujoso en sus colecciones.

II. ¿Qué son las prendas de punto cortadas y cosidas?

Las prendas de punto de cortar y coser son un método versátil de fabricación que implica tomar grandes hojas de tela, cortarlas en piezas más pequeñas y luego coserlas para crear la prenda deseada. Este método es diferente del proceso de tejido totalmente confeccionado, que da como resultado el tejido directo de las prendas con la forma deseada. Las prendas de punto cortadas y cosidas facilitan una variedad de opciones de diseño y se emplean comúnmente en diferentes áreas de la moda.

1. Personajes principales:

(1) Golpe de paneles: los proveedores de material forman inicialmente la tela en paneles grandes. Luego, la empresa de prendas de punto los corta en los componentes deseados de la prenda. Este método promueve diversas opciones de diseño y permite detallar la individualización.

(2) Corte: Los paneles tejidos se cortan según las especificaciones del diseño y se ensamblan con máquinas de coser. Este paso agrega flexibilidad al proceso de confección de prendas y permite patrones complejos.

(3) Flexibilidad del diseño: el método admite una variedad de opciones de diseño, desde simples hasta complejas, y es lo suficientemente flexible como para adaptarse a diferentes estilos y tendencias de moda.

2. El METROfabricación PAGproceso

El procedimiento de cortar y coser juntos para formar prendas de punto se llama fabricación de prendas de punto cortadas y cosidas, y este proceso implica varios pasos críticos que contribuyen al diseño y la funcionalidad finales de la prenda:

(1) Tejido de punto:

El procedimiento comienza cuando los proveedores de telas cosen grandes hojas de tela utilizando máquinas de coser mecánicas. A diferencia de los métodos que implican tejer directamente hilo en el diseño final, la tela de cortar y coser se teje previamente en rollos. La variedad de texturas, gramajes y colores de esta tela es apropiada para diferentes opciones de diseño.

(2) Corte:

Una vez que la empresa recibe la tela, se divide en secciones individuales según el diseño de la prenda. La precisión en este paso es importante para asegurar que las piezas queden colocadas correctamente durante el proceso de montaje.

(3) Cosering:

Los fragmentos se recogen y conectan mediante máquinas de coser. Este procedimiento implica coser los paneles y agregar elementos como dobladillos, bolsillos y cremalleras.

(4) Finalizaring:

Después del ensamblaje, las prendas se someterán a procedimientos como planchado, lavado y recorte que mejorarán su apariencia y asegurarán que cumplan con los estándares de calidad.

4. Beneficios de la moda de cortar y coser

(1) Adaptabilidad del diseño:

Las prendas de punto cortadas y cosidas tienen una variedad de opciones de diseño, que se pueden utilizar para crear prendas tanto simples como complejas. Los diseñadores tienen la oportunidad de experimentar con diferentes patrones y tipos de telas.

(2) Escalabilidad:

Este método es apropiado para la producción a gran escala, lo cual es ideal para producir grandes cantidades de ropa de manera eficiente. Facilita la producción en masa de productos de moda y tiene un gran mercado.

(3) Rentabilidad:

Las prendas de punto cortadas y cosidas suelen ser más rentables para grandes tiradas de producción debido a los menores costos de instalación inicial en comparación con los métodos de prendas de punto totalmente confeccionadas. Permite la producción económica de diversas gamas de prendas.

Facilita la producción económica de diversos tipos de prendas de vestir.

Las prendas de punto cortadas y cosidas se emplean comúnmente en la moda cotidiana y en grandes colecciones destinadas a la producción en masa, lo que proporciona flexibilidad y eficiencia en la producción de prendas. Grandes marcas como Zara y H.&Utilizo este método para crear una variedad de ropa moderna y económica.

III. Las diferencias entre prendas de punto totalmente confeccionadas y cortadas y cosidas

Comprender las discrepancias entre prendas de punto totalmente confeccionadas y cortadas y cosidas es fundamental para tomar decisiones precisas sobre la producción de prendas. Ambos enfoques tienen atributos singulares que influyen en el diseño, el rendimiento y los gastos. A continuación se muestra una comparación de estos dos métodos destacados de tejido.

1. El proceso de producción.

Totalmente de moda Prendas de punto:

- Las prendas se tejen directamente con la forma deseada utilizando máquinas especializadas. Esto incluye todos los componentes del diseño, como patrones y detalles.

- Residuos minimizados: al tomar las medidas adecuadas para reducir los residuos generados por el proceso de fabricación, las prendas de punto totalmente confeccionadas reducirán la cantidad de tela desperdiciada y simplificarán el proceso de fabricación. Sin duda, esto está más en línea con la tendencia actual del desarrollo sostenible.

Cortar y coser Prendas de punto:

- Abastecimiento de telas: se compran grandes cantidades de telas a los proveedores, que luego se dividen en piezas más pequeñas y se ensamblan en prendas.

- Tejido y corte de paneles: grandes hojas de tela pre tejida se dividen en secciones específicas y luego se cosen para crear la prenda final. Este procedimiento implica pasos adicionales de cortar en cubitos y coser.

2. Flexibilidad en el diseño

Totalmente de modaPrendas de punto:

- Diseño de precisión: este método se utiliza para crear diseños intrincados y precisos en la tela a medida que se teje con todos sus detalles presentes. Es perfecto para la moda de alta gama que implica detalle y precisión.

- Una vez terminada la prenda, solo se pueden realizar cambios limitados.

Cortar y coser Prendas de punto:

- Diseño variable: al ofrecer una variedad de opciones de diseño y métodos de construcción, la tela se puede combinar y personalizar. Ideal para una variedad de tipos de moda.

- Después del corte, la tela se somete a un procesamiento posterior, que incluye ajustes y modificaciones durante las etapas de corte y costura.

3. Costo y eficiencia

Totalmente de modaPrendas de punto:

- Costos iniciales más altos: el costo del tejido completamente confeccionado suele ser más alto debido al equipo especializado necesario. Sin embargo, puede generar ahorros tanto en material como en mano de obra con el tiempo.

- Efectivo para grandes producciones: en el caso de lotes pequeños, el costo unitario es alto y solo la producción a gran escala puede reducir los costos de producción.

Cortar y coser Prendas de punto:

- Costos iniciales más bajos: esto generalmente se asocia con costos iniciales más bajos y un enfoque más convencional. Ideal para producción en masa.

- Económico para lotes pequeños: rentable para fabricar grandes cantidades de ropa, adecuada para la moda en general. Debido a su bajo costo unitario, también es aplicable la personalización de lotes pequeños.

4. Calidad y finalización

Totalmente de modaPrendas de punto:

- Acabado sin costuras: Proporciona un acabado superior sin costuras debido a su exactitud en el tejido. Muchas prendas tienen un ajuste superior y una apariencia completa.

- Artesanía elaborada: es ideal para moda de lujo y alta gama. La calidad de la artesanía es primordial.

Cortar y coser Prendas de punto:

- Acabado versátil: Permite una variedad de acabados dependiendo de las técnicas de costura utilizadas. La máxima calidad se deriva de los procesos de montaje y finalización.

- Personalizable: Experto en varios niveles de moda, desde diseños básicos hasta complejos.

Estos dos métodos de tejido tienen sus propias ventajas y son apropiados para diferentes requisitos de fabricación. Las prendas de punto totalmente confeccionadas tienen un grado superior de precisión y una menor cantidad de desperdicio, por lo que son ideales para prendas de lujo y prendas sostenibles. Por el contrario, los géneros de punto cortados y cosidos promueven la flexibilidad y la eficiencia en la producción, lo que los hace apropiados para la producción en masa y diversas opciones de diseño. Comprender estas discrepancias ayudará a las marcas y fabricantes a seleccionar el enfoque más eficaz para sus inquietudes particulares.

IV. Seleccionar el tejido correctotener puesto para tu marca

Seleccionar el método apropiado para fabricar tejidos, ya sea prendas de punto totalmente confeccionadas o prendas de punto cortadas y cosidas, puede tener un efecto significativo en la calidad, el costo y la popularidad de su ropa. Comprender los beneficios y desventajas de cada método lo ayudará a combinar la fabricación de los productos de su marca con los objetivos y las necesidades de los consumidores de su marca.

1. Evaluación de las necesidades de la marca

- Tipo de producto:

Si su marca se especializa en ropa única o de alta gama, las prendas de punto hechas a medida suelen ser más adecuadas para usted. Este método promueve un ajuste superior, un diseño detallado y un acabado suave que está en línea con un comportamiento de lujo y alta gama. Por ejemplo, Loro Piana y Brunello Cucinelli emplean técnicas modernas cuidadosamente elaboradas.

Para las marcas que tienen una audiencia más amplia o necesitan producir mayores cantidades a un costo menor, las prendas de punto cortadas y cosidas son más apropiadas. Proporciona flexibilidad y escala, lo cual es ideal para marcas como Zara y H.&M, que producen grandes cantidades de mercancías.

- Complejidad del diseño:

Si su ropa tiene patrones y formas complejos o requiere un alto grado de precisión, las prendas de punto completamente confeccionadas permitirán incorporar componentes de diseño detallados durante el proceso de tejido. Este método garantiza que todos los componentes del diseño, incluidos patrones y formas intrincados, se incorporen a la prenda desde el primer paso.

Para diseños más sencillos o cuando se experimenta con diferentes estilos, las prendas de punto cortadas y cosidas tienen la flexibilidad de combinar paneles de tela y componentes de diseño, lo que puede conducir a diversas tendencias de moda y cambios más rápidos en la moda.

2. Consideraciones de precio

- Restricciones presupuestarias:

Las prendas de punto totalmente confeccionadas a menudo requieren equipos y habilidades especializados, por lo que al principio es más costoso hacer pedidos pequeños. Sin embargo, una vez que se realizan pedidos más grandes, esto puede generar ahorros a largo plazo al reducir el desperdicio y distribuir los costos laborales sobre el costo unitario. Los géneros de punto cortados y cosidos tienen costos de preparación más bajos y son más adecuados para la producción a gran escala, aunque el costo unitario también será menor para pedidos de lotes pequeños.

- Escala Económica:

Si su marca produce tiradas limitadas o artículos a medida, las prendas de punto totalmente confeccionadas pueden ser más adecuadas a pesar de los costos iniciales más altos. Este método es ideal para confeccionar prendas únicas y de alta calidad que justifiquen la inversión.

Para las marcas que necesitan producir grandes cantidades de prendas de manera eficiente, las prendas de punto cortadas y cosidas ofrecen la escalabilidad y la rentabilidad necesarias para la producción en masa.

3. Calidad y Finalizar

- Calidad de la prenda:

Las prendas de punto totalmente confeccionadas proporcionan un acabado suave y de alta gama que es superior en diseño y construcción. Este método es beneficioso para producir una apariencia y sensación notables en colecciones superiores.

Los géneros de punto cortados y cosidos tienen varias opciones finales según los métodos de costura empleados. A pesar de no tener el mismo nivel de construcción sin costuras que las prendas de punto totalmente confeccionadas, aún tiene un alto grado de calidad cuando se hace con cuidado.

- Durabilidad:

Las prendas de punto a la moda a menudo se asocian con una durabilidad superior y una apariencia más refinada; esto es ideal para mercados de alto nivel que valoran la longevidad y la calidad. Y las prendas de punto cortadas y cosidas ofrecen opciones duraderas para el uso diario y son apropiadas para marcas que se especializan en moda rentable, pero que no comprometen la calidad esencial.

4. Flexibilidad e Innovación

Las prendas de punto modernas son ideales para diseños innovadores y prendas con visión de futuro que requieren precisión y detalle. Este enfoque facilita estructuras de ropa creativas y únicas.

Las prendas de punto cortadas y cosidas están diseñadas para adaptarse fácilmente a las modas populares y los cambios estacionales. Ofrece flexibilidad para crear y modificar rápidamente diseños según las demandas de los consumidores.

La selección del método de fabricación de prendas de punto adecuado se basa en los requisitos específicos de su marca, incluido el tipo de producto, la complejidad del diseño, el presupuesto y la calidad deseada. Los géneros de punto de moda son ideales para producir prendas de alta gama y alta precisión, mientras que los géneros de punto cortados y cosidos son beneficiosos para la versatilidad y la rentabilidad en la producción en masa. Revisar estos factores le ayudará a tomar una decisión informada que se corresponda con los objetivos y la posición de su marca en el mercado.

v. Conclusión

Seleccionar el método de fabricación de prendas de punto adecuado (completo o cortado y cosido) puede tener un impacto significativo en el éxito de su ropa. Cada método tiene sus propias ventajas que son específicas para diferentes necesidades. Desde colecciones de lujo de alta gama hasta producción en masa escalable, existen varias técnicas.

Las prendas de punto diseñadas a la moda son excepcionales porque ofrecen prendas de primera calidad, cortadas con precisión y con poco desperdicio de material. Es perfecto para marcas que se especializan en productos de alta gama, donde la precisión del diseño y la artesanía son esenciales. Por ejemplo, marcas como Loro Piana y Brunello Cucinelli utilizan este método para crear hermosas prendas de punto de alta gama que se centran en los detalles y el ajuste.

Por el contrario, las prendas de punto cortadas y cosidas proporcionan flexibilidad y rentabilidad; por lo tanto, es apropiado para la producción en masa y diversos estilos de moda. Marcas como Zara y H.&Adopto este enfoque para producir de manera eficiente grandes cantidades de ropa de moda y presupuestada.

En MODA GUOUOU, nos especializamos tanto en prendas de punto totalmente confeccionadas como en suéteres regulares hechos de hilo, aportando años de experiencia y tecnología de vanguardia para satisfacer sus necesidades de fabricación. Ya sea que desee la precisión y el lujo de prendas de punto totalmente confeccionadas o el valor del dinero asociado con un suéter básico, nuestras instalaciones pueden producir resultados de calidad que coincidan con la filosofía de su marca.

Investigar como MODA GUOUOU Puede aumentar su fabricación de prendas de punto visitando nuestro sitio web o contactándonos para más información. Podemos ayudarlo a transformar sus ideas de diseño en prendas bellamente diseñadas con el método de fabricación ideal.

English

English Deutsch

Deutsch Français

Français Italiano

Italiano Español

Español Русский

Русский Polski

Polski Nederlands

Nederlands Svenska

Svenska