Introduction

Picture this: your brand launches a custom sweater line. Customers are hooked on the unique designs and eager to wear them everywhere. But after a few washes, things go south. The sweaters lose shape, pill uncontrollably, and the seams begin to unravel. Ouch. Not exactly the brand image you envisioned, is it?

For brands, producing high-quality custom knitted sweaters is more than merely offering a fashionable product; it’s crucial for building trust and loyalty with your customers. A well-made sweater showcases your brand’s dedication to quality and acts as a walking advertisement for your designs. However, with so many knitted sweater manufacturers to choose from, how can you ensure that you are partnering with one that places a high priority on quality?

Here’s why quality matters for brands creating custom knitted sweaters:

- Impress customers: They feel luxurious and comfortable, exceeding expectations.

- Last longer: They’re durable, reducing replacements and keeping customers happy.

- Boost your brand image: They show you care about quality and craftsmanship.

- Minimize returns: Well-made sweaters mean fewer returns and headaches for you.

By prioritizing quality in your custom knitted sweaters, you’re not just building a product; you’re building trust and loyalty with your customers, strengthening your brand reputation in the process. In the following sections, we’ll explore factors like understanding yarn quality, construction techniques, quality control measures, and ethical manufacturing practices – all crucial aspects for ensuring your custom sweaters become cherished pieces in your customers’ wardrobes.

Part 1: What Makes a High-Quality Custom Knitted Sweater?

Creating exceptional custom sweaters requires a focus on three key areas:

- Premium Yarn: The foundation of a great sweater starts with high-quality yarn. Explore options like merino wool for softness, cashmere for ultimate luxury (with extra care needed!), or Pima cotton for breathability. Consider yarn weight (ply), too – thicker yarns create warmer sweaters. Certifications like OCS or RWS ensure ethical and sustainable practices.

- Construction Techniques: How a sweater is built matters! Full-fashioned sweaters offer a tailored fit with minimal seams, while sweaters made by common machines provide more movement but have prominent seams. Look for strong, flat or French seams with even stitching and no loose threads. Finishing touches like reinforced buttonholes and clean hems elevate the overall look and durability.

- Ethical Manufacturing: Today’s consumers value ethical practices. Partner with a manufacturer committed to fair labour and environmental responsibility, aligning your brand with its values.

By focusing on premium yarn, meticulous construction, and ethical practices, you can create custom sweaters that are both beautiful and represent your brand’s commitment to quality and social responsibility.

Part 2: Yarn Quality

Crafting a premium custom knitted sweater starts with the foundation – the yarn. But with a vast array of options, navigating the world of yarn can feel daunting. Fear not! This guide equips you to confidently choose the perfect yarn to bring your custom sweater designs to life.

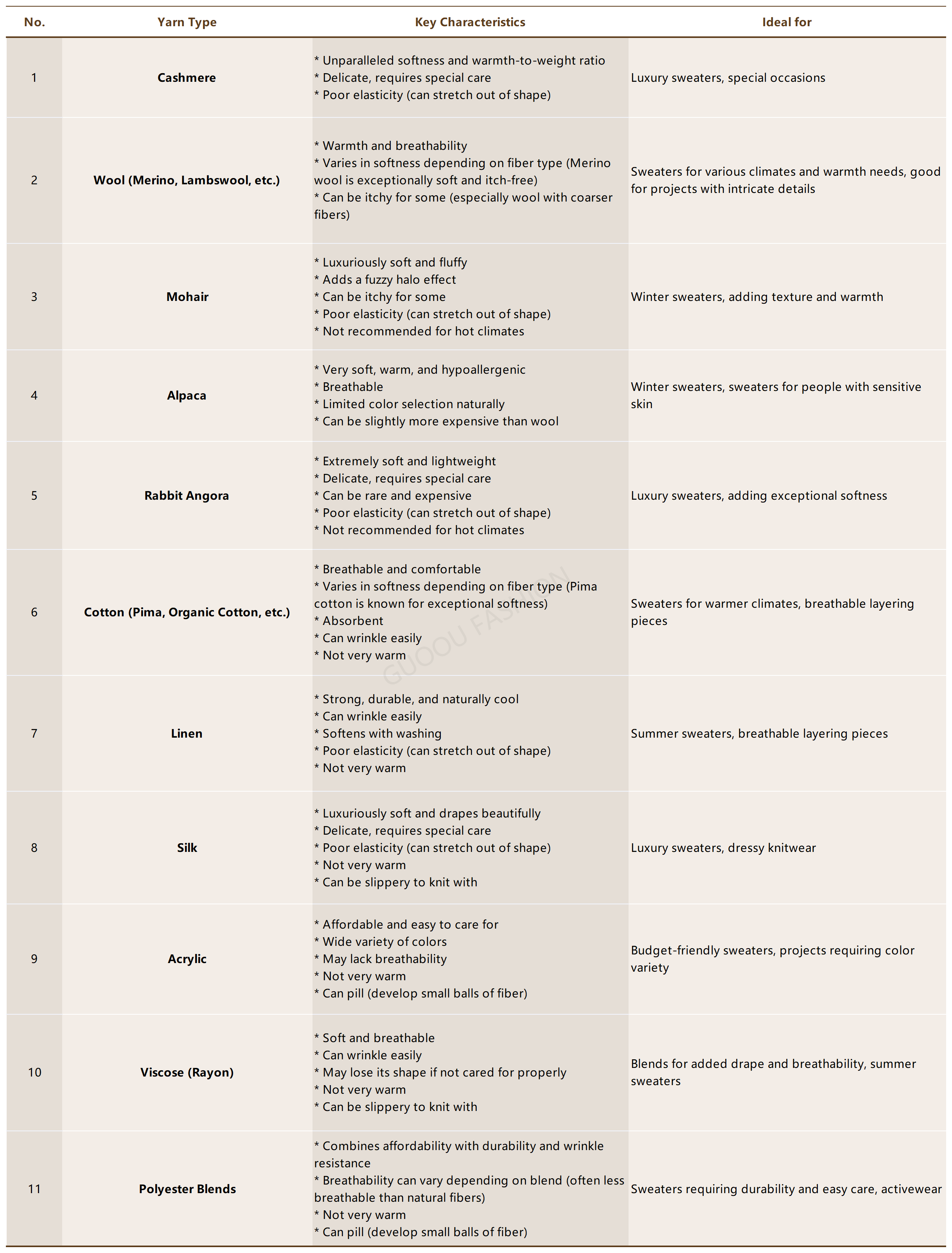

- Demystifying Yarn Types

Wool: The quintessential sweater fibre, wool offers a winning combination of warmth, breathability, and natural stretch. Merino Wool reigns supreme for its luxurious softness and itch-free comfort, while Lambswool provides a budget-friendly alternative with good warmth.

Cashmere: The epitome of luxury, cashmere boasts an unmatched softness and warmth-to-weight ratio. However, its delicate nature demands special care.

Cotton: For breathable and comfortable sweaters, cotton reigns supreme. Pima Cotton takes the crown for its exceptional softness, durability, and beautiful drape, making it ideal for lightweight options. Algodón Orgánico ensures eco-friendly practices throughout the production process.

For unique textures and properties, consider these speciality fibres:

Mohair: Known for its luxurious softness and fuzzy halo effect, mohair adds a touch of whimsy to winter sweaters. Be mindful that it can be itchy for some.

Alpaca: This hypoallergenic fibre offers exceptional warmth and softness, making it a perfect choice for those with sensitive skin.

Linen: Renowned for its cool and crisp feel, linen adds a touch of summer sophistication to sweaters.

2. Understanding Yarn Count (Ply): Finding the Right Thickness

Think of yarn count (ply) as the number of strands twisted together. This primarily affects the thickness of the yarn, but the weight can also vary slightly depending on the fibre content.

Here’s a quick breakdown:

- Fingering Weight (1 ply): These are the thinnest yarns, ideal for lightweight fabrics like summer sweaters or delicate lace projects.

- Sport Weight (2 ply): Offers a good balance between thickness and breathability, making it suitable for year-round wear.

- DK Weight (3 ply): A versatile weight, DK yarn can be used for a wide range of sweaters and climates.

- Worsted Weight (4 ply): This is a common weight for sweaters, creating garments with good warmth and structure for colder weather.

- Bulky Weight (5+ ply): The thickest category, perfect for chunky knits and super-warm winter sweaters.

Remember: While ply is a good indicator of thickness, it’s always wise to check the recommended needle size and finished gauge specified for the yarn you choose. This ensures you achieve the desired drape and look for your project.

Part 3: Knitted Sweater Construction

We’ve explored the magic of yarn quality, and now it’s time to delve into the construction techniques that bring your custom sweater design to life. These techniques significantly impact a sweater’s aesthetics, comfort, and longevity.

Here, we’ll break down the key elements that contribute to a well-made custom sweater:

- Knitting Techniques: Shaping Your Vision

There are three main knitting techniques used to create sweaters, each offering distinct advantages:

- Full-Fashioned: This technique involves shaping the sweater directly while knitting, resulting in minimal seams and a tailored fit. It’s a hallmark of high-quality sweaters, often produced through hand-knitting or by specialized machines.

- Hand-Knitted: This traditional technique involves using needles and yarn to create sweaters stitch by stitch. Hand-knitted sweaters offer unique customization possibilities and a handcrafted touch but require significant skill and time to produce.

- Machine-Knitted: Modern knitting machines can replicate many hand-knitting techniques, including full-fashioned construction. This allows for high-quality, consistent production of custom sweaters at scale.

- Seams

As mentioned before, seams might seem like a minor detail, but they’re the backbone of a sweater’s strength. Here’s what to look for in well-constructed seams:

- Seam Type:

Flat Seams: These lie flat against the garment for a smooth and comfortable feel.

French Seams: These enclose raw edges within the seam, creating a clean and professional finish.

- Stitch Quality: Consistent, tight stitches ensure the seam is strong and secure.

- Clean Finish: No loose threads or raw edges that could snag or unravel.

- Precise Alignment: Seams should align perfectly to create a symmetrical and polished look.

3. Finishing Touches

The finishing touches elevate a custom sweater from ordinary to exceptional. Here are some key elements to consider:

- Reinforced Buttonholes: These can withstand repeated use without stretching or fraying.

- Woven Ends: Securing yarn ends ensures the garment doesn’t unravel over time.

- Clean Hems: A well-made hem adds a polished look and prevents the sweater from losing its shape.

Partnering with a manufacturer who prioritizes meticulous construction techniques is crucial. Look for a manufacturer who can provide samples and clearly explain their quality control processes. This ensures your custom sweaters meet high standards and exceed customers’ expectations.

Part 4: Ensuring Quality Control: From Sample to Production

The journey of a custom sweater doesn’t end with selecting the perfect yarn and construction technique. Meticulous quality control (QC) measures are essential to ensure every sweater meets your high standards and delivers exceptional quality to your customers.

Here’s a glimpse into the quality control process, including an example from GUOOU FASHION:

- Sample Approval

Before bulk production begins, a sample sweater is created based on your specifications. Here’s a breakdown of key elements to examine:

- Overall Look: Does the sweater match the design and colour you envisioned? Are there any mismatched patterns or seams?

- Yarn Quality: Does the yarn feel soft and consistent throughout? Are there any visible defects or irregularities in the yarn itself?

- Construction: Are the seams straight and secure? Are there any loose threads or raw edges? Does the sweater lie flat without bunching or twisting?

- Finishing Touches: Are buttonholes reinforced? Are hems clean and well-executed? Are there any stray threads or imperfections in the finishing details?

- Softness: Does the sweater feel soft and comfortable against your skin? Are there any itchy spots or rough textures?

- Drape: Does the sweater drape nicely or hang stiffly? Does it move gracefully with your body?

- Weight: Does the weight of the sweater feel appropriate for the yarn type and intended use?

- Fit: Does the sweater fit as expected? Is there enough room for movement and layering, if desired?

- Buttonholes and Zippers: Do buttons fasten securely without gapping? Do zippers glide smoothly and easily?

Once you’re satisfied with the sample, it serves as the benchmark for the entire production run.

2. Production Line Inspection

Throughout the production process, various checkpoints ensure consistent quality:

- Material Inspection: Incoming yarn is inspected for defects, weight, and colour consistency.

- Knitting and Assembly Inspection: Fabric panels are checked for accuracy and proper placement before assembly.

- Seam Inspection: Seams are evaluated for stitch quality, alignment, and overall strength.

- Finishing Inspection: The final sweater undergoes a thorough inspection for loose threads, mismatched patterns, and any other imperfections.

3. Final Inspection

Before shipment, each completed sweater receives a final inspection. This ensures all quality control checkpoints have been met, and the sweater is ready to impress your customers.

Reputable manufacturers might implement additional quality assurance measures, such as:

- Knitting Machine Calibration: Regular calibration ensures machines produce stitches to the exact specifications.

- Workforce Training: Investing in employee training on proper techniques and quality standards fosters a culture of excellence.

- Third-Party Inspections: Independent inspections by qualified professionals provide an extra layer of quality assurance.

A Case Study: GUOOU FASHION’s Commitment to Quality

GUOOU FASHION strictly adheres to the AQL 1.0/2.5 standard for their bulk goods inspection as an example of a robust quality control system. The Acceptable Quality Limit (AQL) is a statistically-based sampling plan used in the textile industry to ensure a certain level of acceptable defects. An AQL of 1.0/2.5 means that a very low percentage of defects (around 2.5%) is permitted within a specific sample size. This demonstrates GUOOU FASHION’s commitment to producing high-quality garments that meet the most stringent standards.

Partnering with a manufacturer who prioritizes a robust quality control system guarantees peace of mind and exceptional custom sweaters that will delight your customers.

In conclusion, creating a high-quality custom sweater is a collaborative effort. By understanding the importance of yarn quality, construction techniques, and meticulous quality control, you can ensure your custom sweaters deliver a luxurious and unforgettable experience.

Here are some additional tips to get you started:

- Start with a sketch or digital mockup to visualize your design.

- Consider your target audience and the intended use of the sweater.

- Request samples from potential manufacturers to assess quality firsthand.

- Don’t be afraid to experiment with different yarn types and colours.

By following these steps and leveraging the knowledge you’ve gained, you can create custom sweaters that stand out from the crowd and leave a lasting impression.

We hope this series has empowered you to embark on your custom sweater creation journey!

This concludes the series on custom sweater construction. Stay tuned for future blog posts where we’ll delve deeper into the world of knitwear design and explore exciting new trends!

English

English Deutsch

Deutsch Français

Français Italiano

Italiano Español

Español Русский

Русский Polski

Polski Nederlands

Nederlands Svenska

Svenska