Knitwear holds a prominent position in the global apparel industry, becoming a leader through a combination of practicality and broad appeal. There are two key countries in production and innovation in this industry: the United Kingdom and China. Both countries play a key role in the knitwear market, albeit in very different ways.

The United Kingdom has a long history in the textile industry and is well known for its commitment to quality and craftsmanship in knitwear production. Traditionally, British knitwear has been particularly focused, with a strong emphasis on traditional techniques, so that its final products meet the highest standards.

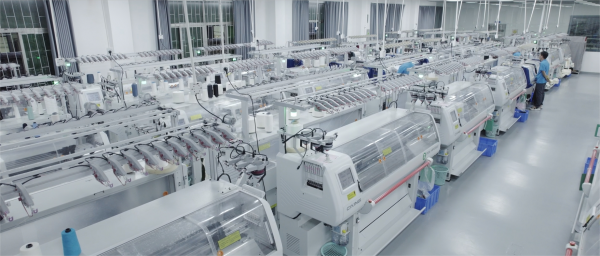

In contrast, China’s knitwear manufacturing approach is characterized by the flexible use of modern technology and efficiency. This has enabled China to produce knitwear on a large scale, effectively meeting the high demand of the global market. China’s manufacturing capabilities contrast with the UK’s emphasis on craftsmanship, highlighting the diverse strategies adopted by the global knitwear industry in response to different market demands.

This article provides a detailed introduction to knitwear manufacturing in the UK and China, focusing on efficiency, craftsmanship, and a comparison of the corresponding characteristics. Through this comparison, we aim to clearly understand each country’s contribution to the knitwear market and the unique factors that drive its success.

Historical Context and Evolution

Exploring the historical backdrop and evolution of knitwear manufacturing in the United Kingdom and China reveals a tapestry woven with tradition, innovation, and cultural heritage. The UK is a bastion of textile craftsmanship, with a heritage rooted in manufacturing artistry. From Yorkshire’s bustling mills to Scotland’s artisanal workshops, the UK’s textile industry embodies resilience, creativity, and a steadfast commitment to quality.

China’s ascent in the textile sector has been remarkable, propelled by rapid economic growth and technological advancements. Embracing automation and digitalization, China has emerged as a leader in textile manufacturing, setting new benchmarks for efficiency and output.

The historical narratives of the UK and China intersect and diverge, shaping current manufacturing techniques in both regions. While the UK values handcrafted excellence and traditional methods in knitwear, China’s focus on mechanization and innovation positions it as a global textile powerhouse. The fusion of these approaches creates a dynamic landscape where tradition meets modernity, and technology intersects with heritage.

Efficiency in Production

Efficiency is a crucial pillar of knitwear production, supporting industry growth and sustainability. The UK and China have embraced innovative technologies to enhance efficiency in manufacturing processes, each with its unique strategy.

In the UK, knitwear production blends traditional craftsmanship with modern technology. Manufacturers integrate advanced knitting technologies to enhance precision and speed without compromising quality. Optimization techniques prioritize meticulous attention to detail while maximizing output, with a commitment to sustainability minimizing waste and environmental impact.

Chinese knitwear manufacturing highlights innovation and scale, leveraging cutting-edge technologies to streamline production. Advanced knitting technology ensures high-quality standards, while sophisticated inventory management and data analytics optimize supply chains and reduce lead times. Industry 4.0 practices further enhance operational efficiency, enabling predictive maintenance and smart manufacturing.

By comparing operational strategies between the UK and China, we gain insight into their distinct approaches to efficiency. While the UK emphasizes craftsmanship and technology, China’s focus on automation and scale leads to different operational strategies. Understanding these nuances provides a comprehensive view of the global knitwear sector’s diversity.

Maintaining Artigianato and Quality

When exploring the intricate world of knitwear production in the United Kingdom and China, one cannot overlook the profound impact of craftsmanship on the industry’s dynamics. The harmonious blend of traditional craftsmanship and modern designs lies at the core of both countries’ approaches to creating high-quality knitwear that resonates on a global scale.

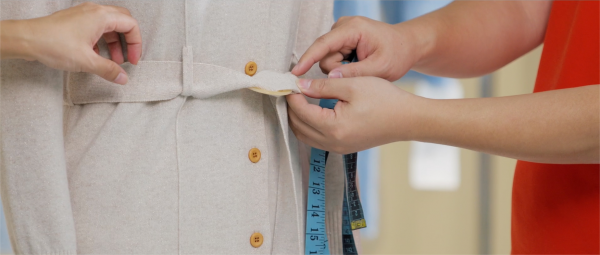

In the United Kingdom, the role of craftsmanship in the knitwear industry is deeply rooted in a legacy of artisanal excellence. British manufacturers uphold time-honored techniques and practices passed down through generations, infusing each garment with a sense of heritage and authenticity. By combining traditional craftsmanship with modern design sensibilities, the UK’s knitwear sector has carved a niche for itself in the global market, attracting discerning consumers who value quality and intricate detailing.

Conversely, Chinese manufacturers have embraced a unique approach to integrating traditional craftsmanship with contemporary aesthetics. Drawing inspiration from centuries-old techniques and cultural motifs, Chinese knitwear designers infuse their creations with a sense of artistic flair and sophistication. By harmonizing traditional craftsmanship with modern design elements, China’s knitwear industry has evolved to cater to diverse consumer preferences, blending artistic tradition with innovative flair.

Both countries employ strategies to ensure product quality while embracing artisanship. In the UK, stringent quality control measures and meticulous attention to detail form the cornerstone of production processes, guaranteeing that each garment meets uncompromising standards of craftsmanship. Chinese manufacturers, on the other hand, leverage a combination of advanced technologies and skilled artisanal labor to achieve a delicate balance between precision and artistry, ensuring that every piece reflects a fusion of heritage and innovation.

Diving into the balance between modern production techniques and traditional craftsmanship in the knitwear sectors of the UK and China unveils a tapestry of creativity, dedication, and meticulous craftsmanship. This delicate balance between past and present not only preserves the rich heritage of knitwear production but also propels both countries towards continued excellence in an ever-evolving industry.

Maintaining Craftsmanship and Quality in Knitwear Manufacturing

When examining the knitwear manufacturing landscape in the UK and China, the profound impact of craftsmanship on their industries is undeniable. The seamless blend of traditional craftsmanship and modern design is central to both countries’ production of high-quality knitwear that captivates a global audience.

In the UK, knitwear manufacturers adhere to time-honored techniques and practices passed down through generations, imbuing each garment with a sense of tradition and authenticity. These British knitwear manufacturers prioritize traditional craftsmanship to ensure the superior quality of their clothing. By merging traditional craftsmanship with contemporary design sensibilities, the British knitwear industry has carved out a niche in the global market, attracting discerning brands that value quality and exquisite details.

On the other hand, Chinese manufacturers have developed a unique approach that combines traditional craftsmanship with modern aesthetics. Chinese knitwear designers draw inspiration from centuries-old knitting techniques and cultural heritage, infusing artistry and sophistication into their creations. By blending traditional craftsmanship with modern design elements, China’s knitwear industry continues to evolve, catering to diverse consumer preferences. While quality remains a priority, Chinese manufacturers are not as singularly focused on traditional craftsmanship as their British counterparts.

Both countries employ distinct strategies to ensure product quality and uphold the legacy of craftsmanship. In the UK, strict quality control measures and meticulous attention to detail form the cornerstone of the production process, ensuring that each garment meets uncompromising craftsmanship standards. Conversely, Chinese manufacturers leverage advanced technology alongside skilled manual labor to balance quality, cost, and production efficiency, ensuring each piece embodies a blend of tradition and innovation.

An in-depth study of the balance between modern production techniques and traditional craftsmanship in the knitwear industries of the UK and China reveals a tapestry of creativity, dedication, and fine workmanship. This harmonious balance between past and present not only preserves the rich heritage of knitwear production but also drives both countries’ relentless pursuit of excellence in an ever-evolving industry.

Choosing the Right Knitwear Manufacturers: UK vs. China

As a discerning European buyer seeking to produce high-quality sweaters, the decision between British and Chinese knitwear manufacturers significantly impacts the quality, cost, and overall production process. While British knitwear manufacturers are celebrated for their craftsmanship and meticulous attention to detail, Chinese manufacturers are increasingly focusing on high-quality craftsmanship, challenging traditional industry perceptions.

British knitwear manufacturers are renowned for their superior craftsmanship, ensuring premium quality sweaters characterized by meticulous sewing, superior finishing, and a commitment to sustainable and ethical production practices. Choosing a British manufacturer guarantees personalized and tailored sweater designs that meet niche market preferences, emphasizing unique craftsmanship and authenticity.

Conversely, Chinese manufacturers are recognized for their cost-effectiveness and mass production capabilities, offering competitive pricing and faster production turnaround times. Although traditionally associated with mass production, many Chinese manufacturers have adopted quality-focused practices, investing in advanced technology and skilled labor to provide knitted products that meet international standards of craftsmanship and durability.

In terms of customization and flexibility, British knitwear manufacturers excel in working closely with European buyers on sweater design, material selection, and production processes, allowing for customized pieces that reflect the buyer’s brand identity and aesthetic preferences. While Chinese manufacturers may be limited in terms of customization options, their continued focus on quality craftsmanship offers European buyers cost-effective solutions and access to a wide range of materials and technologies.

Sustainability and ethical practices are key considerations for European buyers when choosing a manufacturing partner. UK knitwear manufacturers prioritize sustainability, environmentally friendly materials, and ethical labor practices. Meanwhile, Chinese manufacturers have made significant progress in adopting sustainable practices and aligning with environmental values. European buyers working with Chinese manufacturers should conduct thorough due diligence to ensure compliance with sustainability requirements and ethical standards.

In summary, choosing between UK and Chinese knitwear manufacturers to produce sweaters requires consideration of various factors, including craftsmanship, cost-effectiveness, customization options, and sustainability practices. Both UK and Chinese manufacturers offer unique advantages and considerations, providing European buyers with diverse opportunities to produce high-quality sweaters that meet their preferences and market demands.

English

English Deutsch

Deutsch Français

Français Italiano

Italiano Español

Español Русский

Русский Polski

Polski Nederlands

Nederlands Svenska

Svenska