In the ever-evolving realm of fashion, one trend has increasingly carved out its niche: customization. Undeniably, customization has become an essential force in the fashion industry, pushing boundaries and transforming the way consumers perceive and interact with fashion.

Customization is a powerful tool in today’s fashion marketplace – it allows designers to craft clothes that express the unique personality and style preferences of each individual. By harnessing customization, fashion has moved beyond a one-size-fits-all model to a more flexible and personalized approach. This trend is reflected in everything, from bespoke tailoring to personalized accessories, and now, extends to the vibrant world of knitwear.

Indeed, knitwear holds a distinctive place in the fashion landscape. With its infinite capacity for pattern, texture, and color variations, it’s a natural fit for the customization wave. Custom-made knitwear disseminates a message about the person wearing it, their tastes, and personality. It allows the wearer to make a unique fashion statement, showcasing their identity in a beautifully knitted narrative.

The creation of a custom-made knit sweater is a harmonious fusion of artistry and precision, encompassing a sequence of stages that blend together to bring your unique sweater idea to life.

Your Idea, Our Proficiency

The process commences with conceptualization. As a designer or a brand owner, you have a vital role in this initial phase. You have the freedom to create and share a draft or a technical package of your desired pattern. Optionally, you can provide sample pictures or links to sweater styles that captivate you. The idea stage is all about infusing life into your vision and blending creativity with brand style inclinations. The charm of customization lies in its embodiment of your brand, reflecting everything from brand traits, color, and pattern choices to fitting specifics and brand design components such as icons or text.

Next is the design adaptation stage. Utilizing our proficiency in knitwear creation, our design team will scrutinize your concept, blueprint, or inspirational images. Setting your creativity as the foundation, we focus on adjusting and modifying design specifics to ensure your custom sweater flawlessly aligns with your inspiration while being viable for production.

Materials of Importance: Obtaining Premier Quality for Your Sweaters

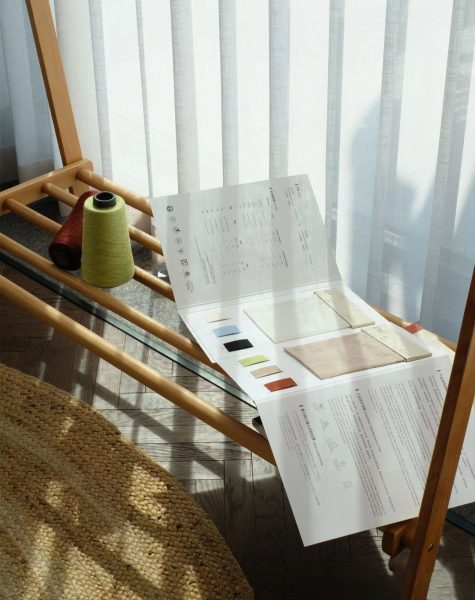

Following this is the material selection stage, of crucial significance. While the design delivers visual appeal and style, the material guarantees comfort, fit, and durability. Concerning knitwear, there’s no ‘universal fit’; the choice of thread ranges from economical materials like cotton or acrylic blends to plush and climate-friendly options like wool and cashmere. Every yarn type embodies unique traits and suits distinct climatic conditions, purposes, and brand inclinations.

When deciding on materials for your knitwear, several parameters come into play: climate, occasion, brand style, and maintenance preferences. The type of thread used can drastically modify the drape, plushness, warmth, and maintenance ease of your garment. At this knit creation phase, investment in superior-quality materials is vital, but it doesn’t necessarily need to be costly. Plenty of affordable thread options offer excellent quality without straining your wallet.

Among the often-used materials, the range starts with acrylic and cotton blends. These are preferred options due to their endurance and ease of maintenance. Acrylic and cotton are machine washable, making them ideal for everyday attire.

Mid-range, we have wool. Wool is an excellent warm material, ideal for winter knitwear. It’s pleasing to touch and extends a plush feel. In the Sahara Desert, a native tribe’s people called the Bedouins wear thin wool clothing to keep themselves cool in the blistering heat. So it is also a high-quality fabric that is breathable and sweat-wicking in summer. However, wool can be somewhat challenging to maintain and might require handwashing or special wool-friendly cleaner.

On the plush side, we introduce premium materials like cashmere. Celebrated for its unmatched softness, lightweight, and warm character, cashmere adds an element of luxury to your custom knit sweater.

The source of these materials is equally vital. Ensuring your materials originate from sustainable and ethical sources not only guarantees quality but also has a positive impact on the environment and the welfare of the workers involved in its production.

Choosing from these materials can be challenging, especially with the thousands of yarn options available in the market. If you’re not particularly familiar with yarns or have a specific budget in mind, worry not. Just share your preferences and unit budget, and we’ll match and recommend 3 suitable yarns for your design absolutely free of charge! To avail of this, please feel free to contact us here.

Sample Production

Once you’ve finalized your yarn of choice, the process moves to the color selection, sample creation, and final stages.

Choosing the hue of your knit is equally significant as selecting the material, reflecting your brand style, influenced by factors such as seasonal color trends or the intended use of the outfit.

Our experts work closely with you to explore an array of colors that perfectly complement your preferred thread. Whether you favor the timeless appeal of neutral shades, the vigor of bold hues, or the subtleness of pastel tones, we guide you toward achieving the color profile of your dreams.

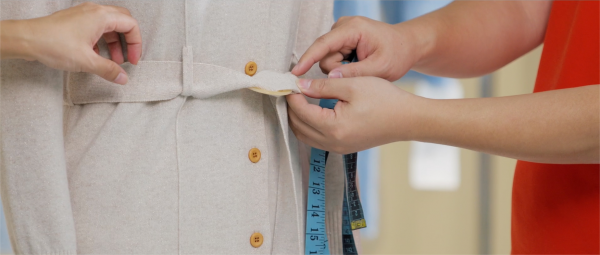

Following color selection, we commence the sample-making process. This phase allows our team to generate samples of your design based on your selected material and color. Sample creation usually spans around 10-15 days, which may vary based on the complexity of your design and the quantity of samples needed.

The seasoned development team meticulously reviews your design, ensuring the samples adhere to your original concept while maintaining the high standards we strive for. During this phase, the team might connect with you providing image or video updates of the custom knitwear. This collaborative approach grants you the opportunity to review the design, texture, and size of the samples remotely and suggest any alterations as needed.

Once all adjustments are addressed, and all elements—design, color, texture—are confirmed, the first samples will be sent to you.

Final Sampling and Bulk Order Procedure

Upon completion of the initial phases of design, material selection, and sample production, it’s time to fine-tune the details and confirm your bulk order—a pivotal step in manifesting your custom knitwear vision.

Initially, it’s vital to confirm the final sample. The samples our development team sends you are crafted with care, always focusing on consistency and quality. We’re dedicated to achieving complete perfection. So, if you notice any details needing adjustment or modification, we’re more than ready to polish and optimize the samples until succeeding in securing your complete satisfaction—ensuring your end product is perfect.

Then, we proceed to decide the hue of your bulk order. You can choose to reproduce your design in multiple colors or maintain a single-hue strategy—the decision is yours.

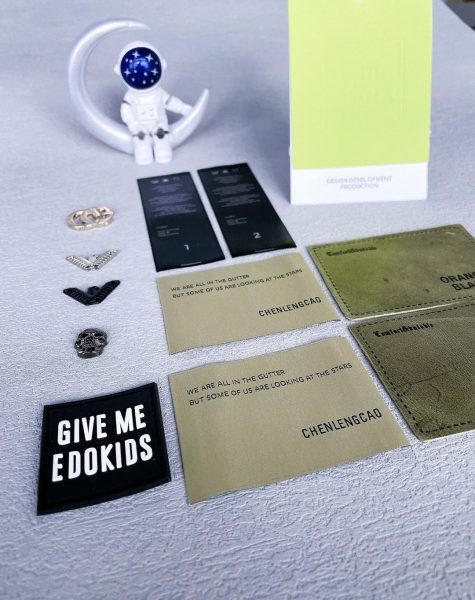

After confirming the samples and hue, we finalize the size and specific quantity of your order. This procedure includes confirming auxiliary materials like labels and packaging.

Customizing brand labels is an essential element of our service offering. You have various options, including main labels, size labels, care labels, hang tags, and packaging bags. Each aspect can be personalized to reflect your brand’s logo and aesthetic, adding a distinct touch.

The Grand Finale: The Realization of Your Custom Knitwear

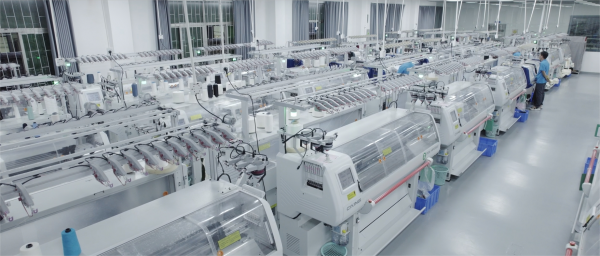

Congratulations! By this phase, your unique, personalized design has transformed from an idea into a high-quality, tangible garment. We are now at the most thrilling stage—the completion of mass production.

Post your final approval of samples, mass production commences. Generally, this phase spans around 30-40 days. The timeline might vary slightly, depending on your ordered quantity and the factory’s schedule. Rest assured, every piece receives the same level of attention to detail and quality norms, irrespective of the order’s size.

On completion of the mass production stage, the end of your customization process is fast-approaching. In this comprehensive process, you’ve envisioned a design, chosen materials, selected hues, perfected prototypes, and signed off on mass production. At each stage, you conveyed your needs and expectations, received expert guidance, and clear, concise updates.

Ready to bring your custom knitwear to life? It’s time to take the first step. Connect with us today for your consultation, and let’s co-create something magnificent. You can reach us via our contact page or email us directly at mildred@guooufashion.com. Unleash your creativity and let your custom knitwear creation process commence!

English

English Deutsch

Deutsch Français

Français Italiano

Italiano Español

Español Русский

Русский Polski

Polski Nederlands

Nederlands Svenska

Svenska