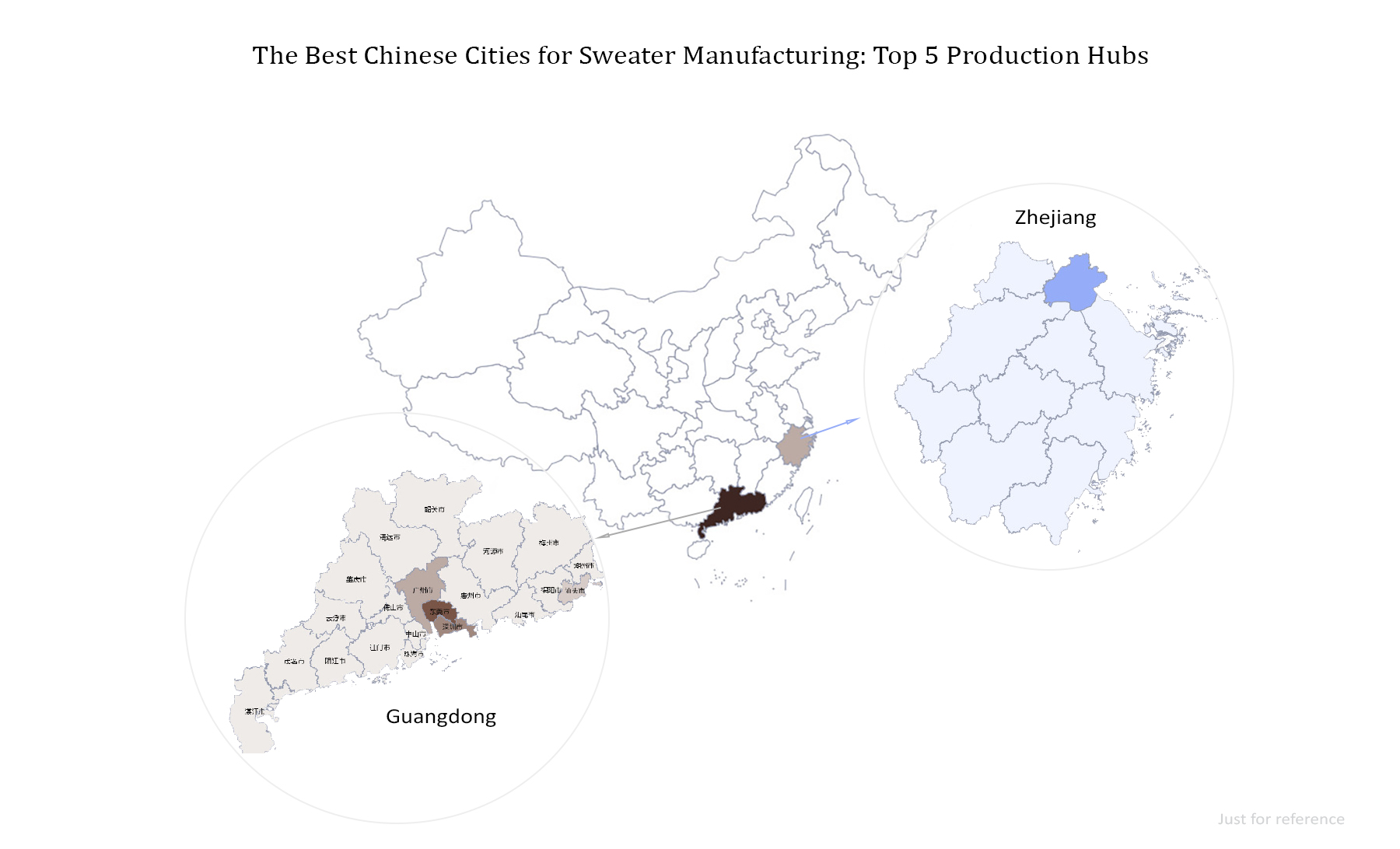

China is acknowledged as a leading powerhouse in the manufacturing of sweaters; this production is significant for a large portion of the world. From high-end fashion to budget-friendly everyday wear, Chinese cities have a significant role in meeting the diverse demands of the market.

This article intends to explore the most popular cities in China for sweater creation by highlighting the most important production centers. We will discuss their specializations, contrast their benefits, and assist you in determining which city is most appropriate for your business endeavors.

Ⅰ. How to choose the most popular cities

When selecting a city in China for the manufacturing of sweaters, several important factors should be considered. Each factor has a significant impact on the efficiency, cost, and overall effectiveness of a manufacturing facility for your business endeavors.

- Capacity for production

Production capacity is the maximum volume of sweaters that can be produced in a city. This includes the capacity to scale operations and take large orders with efficiency. Cities with large production capabilities, such as Tongxiang and Dongguan, are best suited for companies that want to place large orders or who require consistent, large output volume.

High production volume enables manufacturers to fulfil your order requirements and deadlines, which is important for maintaining inventory levels and satisfying consumer demand.

- The quality of the manufacturing process

The quality of the manufacturing process includes the precision, longevity, and craftsmanship of the sweaters produced. Factors that affect quality are the technology employed, the workers’ skill level, and the degree to which they follow quality control rules. Cities like Dongguan and Shenzhen are celebrated for their superior manufacturing processes, particularly in the production of fine-mesh and high-end sweaters.

High-quality manufacturing promotes the production of products that are industry-leading and have a high degree of customer satisfaction, this decreases the likelihood of returns and increases the brand’s reputation.

- Efficiency of the supply chain

Efficiency in the supply chain is concerned with the logistics of obtaining materials, manufacturing processes, and distribution channels. Cities with extensive supply chain networks, such as Shenzhen and Dongguan, have streamlined processes that can reduce lead times and lower costs associated with sending off goods. Effective supply chains are crucial to providing timely and efficient service.

A successful supply chain promotes efficiency and ensures that raw materials and finished products flow easily through the manufacturing process.

- Cost-Effectiveness

Cost-effectiveness is concerned with both the production of goods and the labor expended in their creation. Different cities have different prices that are dependent on the local economy and labor market. For instance, Shantou is associated with its inexpensive production of sweaters, while cities like Guangzhou and Shenzhen have a higher cost of production but provide other benefits.

Understanding the cost structure has a positive effect on budgeting and price setting. This ensures that you receive the greatest possible value for your money while still maintaining a competitive price.

- Skilled Labor Capacity

Skilled labor availability is concerned with the presence of proficient and trained employees in the city. Cities with a large supply of skilled workers, such as Dongguan and Shenzhen, can produce superior manufacturing and innovative solutions. Having access to skilled workers is important for creating beautiful and intricate sweaters. Skilled labor impacts the overall quality and efficiency of production. Cities with a robust workforce can handle intricate designs and maintain high production standards.

- Sources for Data and Insights

To make informed decisions about sweater manufacturing cities, refer to various authoritative sources:

- Industry Reports: Provides comprehensive data on the textile industry and production trends.

- Manufacturer Reviews: Offers real-world feedback on manufacturers from businesses and customers.

- Trade Publications: Features articles and reports on textile manufacturing standards and innovations.

Ⅱ. Detailed Profiles of the Top 5 Cities

When choosing a city for sweater manufacturing in China, understanding the unique attributes of each hub is crucial. Here’s an in-depth look at the top five cities renowned for their sweater production capabilities.

- Dongguan, Guangdong

Dongguan, located in Guangdong Province, is a key player in China’s sweater manufacturing industry. Known for its advanced production facilities, the city specializes in both high-end and cost-effective sweater production. Dongguan’s strategic location near major ports in Guangzhou and Shenzhen enhances its appeal as a manufacturing hub.

- Strengths

High-Quality Production: Dongguan is celebrated for its expertise in producing fine-gauge and high-quality sweaters. The city’s manufacturing facilities utilize advanced technology and adhere to strict quality control standards. Dongguan’s Textile Industry highlights its reputation for excellence in textile production.

Proximity to Ports: Its location offers logistical advantages, facilitating quick access to international markets and reducing shipping times and costs.

Competitive Pricing: Thanks to cost-effective labor and material sourcing, Dongguan provides competitive pricing for high-quality sweaters, making it an attractive option for various business needs.

- Challenges

Regulatory Compliance: Manufacturers in Dongguan face challenges related to environmental regulations and sustainability practices. China’s Environmental Regulations impact production practices and may require adherence to stringent standards.

- Tongxiang, Zhejiang

Tongxiang particularly Puyuan Town, is known as China’s largest domestic hub for wool sweater production. The city is integral to the wool sweater supply chain, with a focus on high-volume production. Puyuan is a central player in meeting Chinese domestic demand for wool sweaters.

- Strengths

High Volume Production: Tongxiang produces nearly 700 million wool sweaters annually, showcasing its immense production capacity. The city’s focus on volume production helps meet large-scale domestic demands. Puyuan’s Wool Industry underscores its role in the global sweater market.

Specialized Manufacturing Capabilities: Tongxiang excels in standardized wool sweater manufacturing, offering reliable production with consistent quality for bulk orders.

- Challenges

Customization Limits: Tongxiang is less equipped for intricate or highly customized designs, focusing instead on standardized, high-volume production.

- Guangzhou, Guangdong

Guangzhou is a major hub for fast fashion and low-cost sweaters. Known for its extensive wholesale market, the city caters primarily to the fast fashion sector, focusing on high-turnover garments at affordable prices.

- Strengths

Fast Fashion Hub: Guangzhou’s role as a center for fast fashion is well-established, with numerous suppliers specializing in low-cost, high-volume sweater production. Guangzhou’s Fast Fashion Industry highlights its significance in the global fashion supply chain.

Cut and Sew Knitwear: The city is known for its cut-and-sew knitwear, focusing on producing knitwear through basic cutting and sewing techniques.

- Challenges

Higher Costs: Although Guangzhou is known for low-cost production, the costs related to yarn sourcing and overall production may be higher compared to cities with lower operational costs.

- Shenzhen, Guangdong

Shenzhen stands out for its technological advancements and focus on high-end, fashionable sweaters. The city’s modern manufacturing infrastructure supports its reputation as a leader in producing innovative and premium sweater designs.

- Strengths

High-Tech Manufacturing: Shenzhen’s use of advanced technology and automation in sweater manufacturing positions it as a leader in producing high-end, fashionable garments. Shenzhen’s Innovation highlights its cutting-edge production capabilities.

Strong Export Capabilities: The city’s robust export infrastructure supports its extensive international trade, making it a key player in the global sweater market.

- Challenges

Higher Costs and Competition: Shenzhen’s advanced technology and high-skilled labor come with higher costs. Additionally, the competitive manufacturing environment may impact pricing and availability.

- Shantou, Guangdong

Shantou is known for its specialization in low-cost sweaters and chunky knitting techniques. The city’s focus is on producing affordable sweaters by replicating designs from other regions, making it a cost-effective option for many businesses.

- Strengths

Cost-Effective Production: Shantou’s ability to offer low-cost sweater production is a significant advantage. The city excels in replicating designs and using less expensive materials to meet budget constraints. Shantou’s Textile Industry highlights its cost-effective production capabilities.

Expertise in Chunky Knitting: The city’s proficiency in coarse knitting and hand crocheting makes it a suitable choice for businesses requiring basic, bulk and low-cost sweaters.

- Challenges

Quality Variability: Shantou’s focus on cost-effectiveness may lead to inconsistencies in quality and material standards, which can impact product durability and customer satisfaction.

Ⅲ. Comparative Analysis

When evaluating the top cities for sweater manufacturing in China—Dongguan, Tongxiang, Guangzhou, Shenzhen, and Shantou—it’s essential to compare their strengths and weaknesses. This comparative analysis will help you determine which city aligns best with your business needs, whether you’re focusing on quality, cost, volume, or innovation.

- Production Capacity

Dongguan and Tongxiang excel in production capacity. Dongguan’s manufacturing facilities are well-equipped to handle both high-end and cost-effective production on a large scale, making it ideal for businesses with diverse needs. Tongxiang, on the other hand, is specifically known for its massive wool sweater output, with nearly 700 million sweaters produced annually.

Guangzhou is more geared toward fast fashion and low-cost items. Shenzhen focuses on high-tech, high-quality production and Shantou on low-cost, coarse knitwear.

- Quality of Manufacturing

Dongguan and Shenzhen stand out for their high-quality manufacturing. Dongguan’s advanced technology ensures top-notch quality for fine-gauge sweaters, while Shenzhen’s high-tech infrastructure supports premium, fashionable designs.

Tongxiang is known for its robust production capabilities but is less focused on intricate designs, making it more suited for standardized wool sweaters. Guangzhou focuses on basic cut-and-sew knitwear. Shantou offers cost-effective solutions with coarse knitting techniques, which might result in variability in quality.

- Cost-Effectiveness

Shantou is the most cost-effective city, specializing in low-cost sweaters and using less expensive materials. This makes it an ideal choice for businesses looking to minimize production costs.

Guangzhou also offers competitive pricing but focuses on the fast fashion sector, which might impact material quality. Dongguan and Tongxiang provide a balance of quality and cost, with Dongguan being slightly more cost-effective due to its efficient labor and material sourcing. Shenzhen, with its high-tech manufacturing, comes at a higher price point but offers superior quality.

- Specialized Capabilities

Shenzhen is notable for its technological advancements and high-end fashion capabilities, ideal for innovative and premium designs. Tongxiang specializes in large-scale wool sweater production, making it a leader in that niche.

Dongguan provides a wide range of production capabilities, including both high-quality and cost-effective solutions. Guangzhou focuses on fast fashion with cut-and-sew knitwear, while Shantou excels in coarse knitting and replicating designs from other regions.

- Supply Chain Efficiency

Dongguan and Shenzhen benefit from their proximity to major ports in Guangzhou and Shenzhen, which enhances their supply chain efficiency. This proximity allows for faster shipping times and reduced costs.

Guangzhou also offers strong supply chain capabilities due to its central location in the Pearl River Delta, a major logistics hub. Tongxiang’s supply chain is focused on domestic distribution, which may limit its export efficiency. Shantou’s supply chain is more focused on low-cost production and may not be as streamlined for international trade.

- Choosing the right city for sweater manufacturing depends on your specific needs:

Dongguan: Ideal for high-quality and cost-effective production with robust logistics.

Tongxiang: Best for large-scale wool sweater production with specialized manufacturing.

Guangzhou: Suitable for fast fashion with cut-and-sewn knitwear and a strong supply chain.

Shenzhen: Perfect for high-end, technologically advanced sweaters with higher costs.

Shantou: Most cost-effective for basic, coarse knitwear with a focus on low-cost production.

Understanding these differences will help you select the city that best fits your business requirements, balancing quality, cost, and production capabilities.

Ⅳ. Industry Trends and Future Outlook

Both sweater design and production are changes over a period as impelled by changing consumer preferences, technological conditions, and economies worldwide. Any comprehension of such tides permits companies to adapt their strategies in response and, thus, maintain competitiveness within the market.

- Sustainable and Ethical Production

The textile industry is beginning to approach sustainability in earnest. The concern for the environment and of ethical production in the hearts of consumers and brands has raised a demand for raw materials that are friendly to the eco-system and manufacturing that is sustainable.

Ethical Labor Practices- Emphasis has grown more on fair labour practices plus transparency in the supply chain. A report on Ethical Fashion provides insights into how important good working conditions are for production.

- Technological Advancements

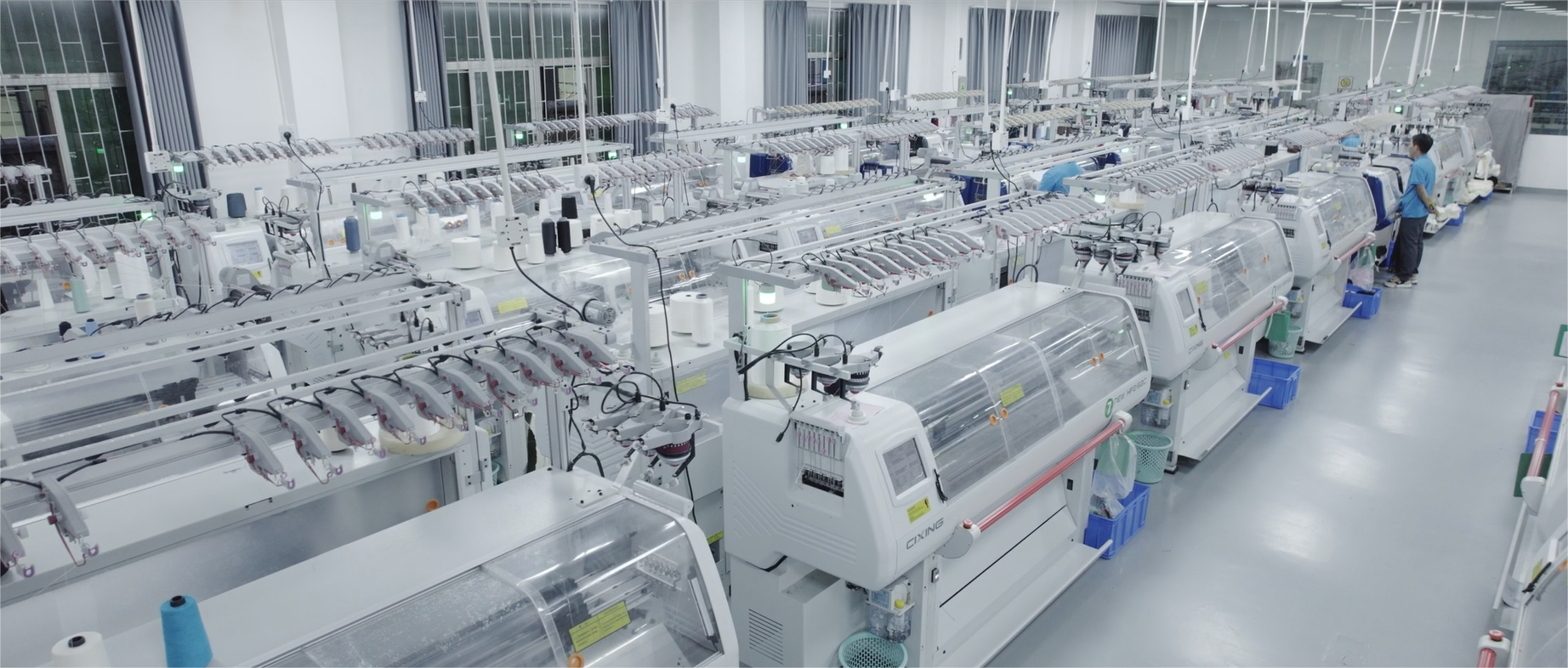

Automation and AI have been adopted by many other industries; the sweater knitwear sector is seeing companies embrace it in their production environments, leading to increases in both efficiency and the quality of final products. Advanced machinery and Artificial Intelligence are reducing manual intervention on the factory floor, thereby cutting down human errors, bringing in consistency, and improving accuracy. 3D Knitting Technology enables more intricate design possibilities while reducing fabric wastage, with low adoption but high potential value according to ” recent advances” since covered only last month.

- Market Demand for Innovative Designs

The need for new, creative and stylish designs is on the rise; hence, manufacturers are forced to venture into new materials, techniques and styles. Fashion Trends: Emerging fashion, and to keep up with fashion trends, it is necessary to follow Fashion Forecasting that provides insight into upcoming fashion trends & styles.

Ⅴ. How to Choose the Right City for Your Business

Choosing the right city for sweater production involves a multivariate approach to confirm that it fits with your business requirements and goals for the item. The following will support this important decision:

- Define Your Priorities

First, know what you want most for your business:

Choosing the right city means quality, cost, production capacity, and logistics efficiency are met. Exclusively weigh what each city has to offer against your business priorities before making an informed strategic decision in line with your long-term objectives.

Feel free to reach out to us, GUOOU FASHION, for further clarification or personalized recommendations. You may also contact local trade associations for more insights into the matter. We will provide valuable resources and networks as you make informed choices.

- Evaluate Production Capabilities

Assess each city’s production capabilities based on your specific needs:

Capacity and Technology: Evaluate whether the city’s production capacity and technological advancements align with your requirements. Textile Manufacturing Capabilities provides insights into different manufacturing capabilities.

Specialization: Consider if the city specializes in the type of sweaters you need. For example, Tongxiang is known for basic sweaters, while Shenzhen excels in high-tech fashion.

- Consider Logistics and Supply Chain

Examine the logistical advantages and supply chain efficiency of each city:

Proximity to Ports: The proximity of such cities as Dongguan and Shenzhen to major ports can influence shipping costs and time.

Supply Chain Networks: Appraise how effective and reliable the supply chain is within each city. Supply Chain Management provides tools for evaluating supply chain networks..

- Review Costs and Budget

Review the cost structures of every city;

Production Costs: Compare raw material costs, labor costs, and production expenses. Shantou is low-cost but may have higher technology-related costs as compared to Shenzhen.

Additional Expenses: Logistic factors should also be taken into consideration along with any additional tariffs or regulatory compliance issues. The final word is the Cost Analysis word.

- Assess Quality and Ethical Standards

Ensure that the city meets your quality and ethical standards:

Quality Control: Look into the quality control measures and manufacturing standards in each city. Quality Standards offers information on industry quality standards.

Ethical Practices: Check if the manufacturing practices align with your company’s ethical values and sustainability goals.

- Visit and Verify

Factory Visits: Visit factories to check the infrastructure, talk to the manufacturers in person, and assess their capabilities.

Local Insights: Get insights from local industry experts and suppliers for better decision-making on the subject.

You can select the city that will best complement your business objectives and pave the way for a successful manufacturing partnership with evaluating these factors.

Ⅵ. Conclusion

The selection of the appropriate city for sweater manufacturing is crucial and can have a remarkable effect on your business. With the individual profiles and comparative analysis of Dongguan, Tongxiang, Guangzhou, Shenzhen, and Shantou, you are well-equipped to understand fully what each city has to offer, both in terms of advantages and disadvantages.

Picking the right city means quality, cost, production capacity, and logistics efficiency have to be in balance. Evaluate what each city can offer very critically and match these against your business priorities to make a strategic decision that will help you meet your long-term goals.

If you need more help or some personalized advice, consider reaching out to us GUOOU FASHION or local trade associations for further insights. We will provide valuable resources and connections to help you make informed decisions.

English

English Deutsch

Deutsch Français

Français Italiano

Italiano Español

Español Русский

Русский Polski

Polski Nederlands

Nederlands Svenska

Svenska