Custom knit sweaters are no longer confined to exclusive school uniforms or high-end boutiques. Today, they’ve become a symbol of personalized style and branding, adorning everything from corporate teams to social media influencers.

Now, consumers are increasingly seeking unique items that reflect their individuality. Custom knit sweaters allow for complete design control, letting you express your brand identity. Knitting technology advancements have also streamlined the custom sweater production process. This, in turn, has made it more accessible and affordable for smaller businesses. And, online platforms have made it easier than ever to connect with custom knitwear manufacturers, fostering a global marketplace with a wide range of options.

However, when first getting into custom knitwear, one question often arises: “How much does it cost?” The answer, unfortunately, isn’t a simple one. The cost of a custom knit sweater is influenced by a variety of factors, which we’ll explore in detail throughout this blog post.

So, grab a cup of tea, settle in, and let’s unravel the cost equation behind your dream custom knit sweater!

Key Factors Affecting the Cost of Custom Knit Sweaters

Demystifying the cost behind your dream custom-knit sweater can feel like untangling a ball of yarn. But fear not! By understanding the key factors that influence the price, you can navigate the process with confidence. Here’s a breakdown of the main elements that contribute to the final cost:

Key 1: Material Selection: The Fabric of Your Dreams (and Budget)

The type of yarn you choose plays a big role in determining the cost of your custom-knit sweater. Here are some popular choices, along with their unique features and price points:

- Wool: Renowned for its warmth, softness, and durability, wool comes in various grades like Merino wool and lambswool. Generally, finer wool like Merino tend to be more expensive.

- Cashmere: The epitome of luxurious softness, cashmere offers an unmatched feel but comes at a premium price.

- Cotton: A breathable and affordable option, cotton sweaters are perfect for year-round layering. Organic cotton or Pima cotton varieties might influence the cost slightly [https://textileexchange.org/app/uploads/2022/05/Challenges-FAQ-Guide-Getting-Started-2022.pdf]

- Acrylic Blends: Budget-friendly and often machine-washable, acrylic blends are a popular choice for everyday wear. However, they may be more prone to pilling (the formation of small balls of fiber on the fabric’s surface).

- Alpaca: Known for its warmth, softness, and durability, alpaca fiber can be more expensive due to its limited production [https://en.wikipedia.org/wiki/Alpaca_fiber].

- Linen: An eco-friendly option, linen offers a sustainable and breathable choice. However, it might require special care instructions.

- Recycled Fibers: Choosing recycled materials can add a sustainable element to your custom sweater, potentially affecting the cost depending on the processing involved.

Explore our blog post on “5 Basic Tips for Custom Knitwear Material Selection” for more in-depth fabric comparisons.

To learn more about sustainable materials for eco-friendly custom sweaters, you can contact us to get you more yarn solutions for free.

Remember, the ideal material selection depends on your desired look, budget, and intended use for the sweater.

Key 2: Sweater Design Complexity

The beauty of custom knit sweaters lies in their ability to transform from simple staples to works of intricate design. However, this design complexity can also influence the overall cost. Here’s a closer look at how different design elements impact the price tag:

- Knits: Some beautiful raised patterns, like Cable Knits, add a touch of texture and visual interest. But beware! They require more yarn to create the raised cables and additional labor to knit them. This translates to a higher cost compared to simpler knit patterns.

Likewise, for truly elaborate designs with intricate details and logos, Jacquard weaving comes into play. This technique uses a special loom to create complex patterns directly into the fabric, often requiring specialized skills and a higher price point [https://en.wikipedia.org/wiki/Jacquard_machine]

- Colorwork: Want to add vibrant pops of color with multiple yarn colors? While visually stunning, colorwork patterns necessitate more yarn changes and planning, increasing production time and potentially the cost.

- Embellishment Extravaganza: Adding a touch of sparkle with beads, sequins, or patches can personalize your sweater. However, these embellishments typically require additional time and labor for secure attachment, influencing the final cost.

- Stitches and Speed: The type of knit stitch used can also subtly affect production speed and potentially the cost. Here’s a quick breakdown of two common stitches:

- Jersey Stitch: This fundamental stitch creates a smooth, even fabric and is generally the fastest to knit, keeping costs potentially lower.

- Full cardigan Stitch: This stitch creates a ribbed texture and is slightly slower to knit compared to stockinette. While the cost difference might be minimal, it’s a factor to consider for very large or complex designs.

Key 3: Material Weight

When it comes to custom knit sweaters, material weight plays a crucial role in both function and cost. But what exactly influences the weight of your sweater, and how does it translate to price? Let’s untangle this yarn-based mystery:

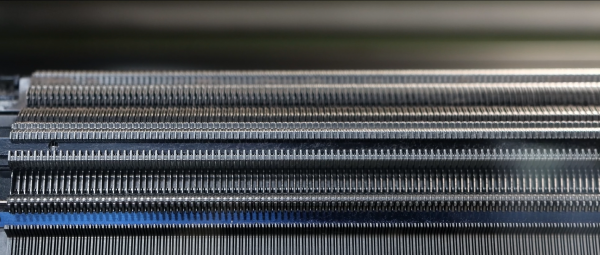

- The Needle

Just like paintbrushes come in a variety of sizes, knitting needles come in a variety of sizes. The size of the needle you choose because of the pattern you’re designing or the functionality you want can significantly affect the weight of your final sweater.

- Thicker Needles (e.g., 3GG or 5GG): These needles create larger stitches, resulting in a thicker, bulkier sweater that uses more yarn and potentially increases the cost.

- Thinner Needles (e.g., 12GG or 14GG): These needles create smaller stitches, leading to a lighter, more delicate sweater that uses less yarn, potentially lowering the cost.

- Stitches: From Jersey to Half Cardigan

The specific knitting technique (or “knit”) used can also affect weight. Here are two common examples:

- Jersey Stitch: This fundamental stitch creates a smooth, even fabric with a medium weight.

- Half-Cardigan Stitch: This stitch creates a thicker, more textured fabric compared to Jersey Stitch. Sweaters knitted entirely with Half-Cardigan Stitch will naturally be heavier and potentially more expensive than those using Jersey Stitch.

- Layering Up for Thickness: Playing with Yarn Quantity

Sometimes, the design concept might call for a thicker fabric without changing the needle size. In such cases, manufacturers can adjust the weight by using more yarn.

- Single Thread: This is the most common approach, using one strand of yarn to create the sweater.

- Double or Multiple Threads: When a thicker fabric is desired, manufacturers might use two or more strands of yarn held together while knitting. This naturally increases the weight and potentially the cost.

- The Yarn Itself: A Matter of Inherent Weight

Different yarn types inherently have varying weights. Here’s a quick comparison:

- Lighter Yarns: Cashmere, known for its luxurious softness, is a lightweight yarn. Sweaters made with cashmere will naturally be lighter than those made with heavier yarns.

- Heavier Yarn: Viscose blended yarn is smooth, cool, anti-static, and can be dyed brilliantly, making it suitable for spring and summer knitwear, but is naturally heavier than lighter yarns.

Understanding the interplay between these factors – needle size, knit type, yarn quantity, and inherent yarn weight – empowers you to make informed choices about the weight and potential cost of your custom knit sweater.

Key 4: Level of customization

Custom knit sweaters shine in their ability to be personalized, but these customizations can also influence the cost. Let’s delve into how different customization options affect the price tag:

- Logo Love

Adding a logo to your sweater can elevate your brand identity. However, the complexity of the logo significantly impacts the cost. Here’s why: A small, simple logo is generally less expensive than a large, intricate one with many details. The chosen method of applying the logo also plays a role. Embroidery offers a classic, professional look but can be more expensive for complex designs. Appliqué involves attaching pre-cut fabric shapes, which can be a quicker and potentially more affordable option for simpler logos. Chenille embroidery adds a textured, raised effect but might be pricier due to the specialized materials used.

Meanwhile, from functional buttons and zippers to stylish tassels and trims, unique decorations can elevate your custom sweater. However, each decoration adds a layer of customization that requires additional time and materials, potentially affecting the price.

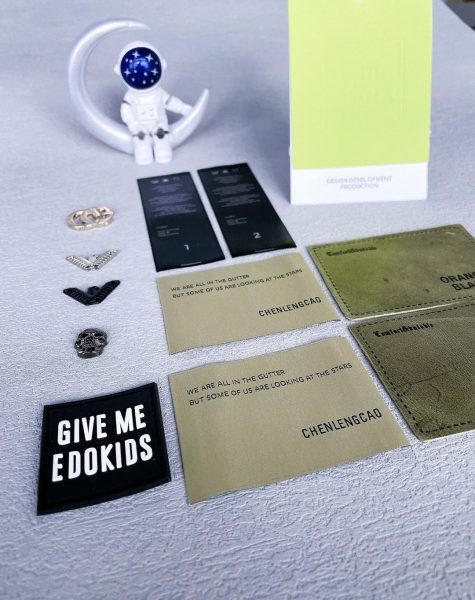

- Brand Identity from the Inside Out: Custom Labels

Taking your custom sweater to the next level often involves custom labels. These can include:

- Main Label: This identifies your brand and provides information like garment care.

- Size Label: Ensuring proper fit requires accurate size labeling.

- Care Label: Clear care instructions help maintain the quality of your sweater.

- Hang Tags: These informative tags can showcase your brand and product details.

- Packaging Bags: Custom packaging adds a professional touch and can be factored into the overall cost.

While custom labels can elevate your brand presentation, they add another layer of customization that may influence the final price.

By understanding how customization options impact cost, you can strike a balance between adding a personal touch and staying within your budget.

Key 5: Order Quantity Counts

The number of sweaters you order can significantly impact the overall cost per unit. This economic principle known as “economies of scale” plays a crucial role in custom knitwear production.

Imagine a manufacturer has fixed costs associated with setting up production for a particular sweater design. These costs might include creating a sample, preparing machinery, and sourcing materials. Regardless of whether they produce 10 sweaters or 100, these initial costs remain relatively constant.

Here’s where economies of scale come into play. When you order a larger quantity, the manufacturer can spread these fixed costs over a greater number of units. This translates to a lower cost per sweater, making larger orders generally more affordable on a per-unit basis.

Many custom knitwear manufacturers establish a Minimum Order Quantity (MOQ). This refers to the minimum number of sweaters they require per order, typically for a specific style and color. Knowing the MOQ allows you to plan your production effectively.

For instance, at GUOOU FASHION, our MOQ is 100 pieces per style/color. This means your initial order needs to include at least 100 sweaters of the same design and color. While this might seem like a high number for smaller businesses or personal projects, it’s important to consider the cost benefits associated with larger orders.

Get the Best Value for Your Custom Knit Sweater

Now that you’ve demystified the factors influencing the cost of custom knit sweaters, it’s time to translate that knowledge into action! Here are some key tips to ensure you get the best value for your investment:

- Shop Around and Compare Quotes

Don’t settle for the first quote you receive. Get quotes from at least 3 different custom knitwear manufacturers. This allows you to compare pricing structures, turnaround times, and overall service offerings. However, remember that the lowest price shouldn’t be the sole deciding factor.

Do note: Prioritize quality and look for manufacturers with a proven track record of high-quality workmanship and materials, such as those with BSCI/GRS certificates.

- Time is of the Essence: Considering Turnaround Time

When comparing quotes, consider the turnaround time (production and shipping) alongside the price. This is especially crucial for time-sensitive orders. Clearly communicate your desired deadline to each manufacturer when requesting quotes. This allows them to provide an accurate estimate of when you can expect your custom knit sweaters to be delivered.

Optimizing Costs for Your Custom Knit Project

Having a budget in mind is essential when venturing into custom knitwear. Here are some strategies to help you optimize costs without compromising on quality:

- Negotiation Power: The Benefits of Larger Orders

Remember the concept of economies of scale from Key 5? Negotiation comes into play here. Once you’ve identified a manufacturer you trust, consider negotiating a slightly lower price for a larger order quantity. This leverages the manufacturer’s ability to spread fixed costs over more units, potentially leading to a per-unit price reduction.

- Design Simplicity: Less is More (Sometimes)

While intricate designs can be stunning, they often come at a premium. Consider simplifying your design to potentially reduce costs. Here are some ideas:

- Focus on a single bold color or a limited color palette.

- Opt for classic and clean silhouettes instead of complex patterns.

- Minimize the number of different sizes you offer, especially for initial orders.

- Material Selection: Striking the Balance

The type of yarn you choose can significantly impact the cost of your sweater. While luxurious materials like cashmere are tempting, explore alternative options that offer a good balance of quality and affordability.

If after reading many articles, you still don’t know how to specifically choose yarn. It doesn’t matter, GUOOU FASHION is good at providing alternative yarn solutions when giving you a quote. They may use videos or send samples to demonstrate the feel and quality of different yarn options. This allows you to make an informed decision that fits your budget and desired sweater features. [Get in touch for free yarn solutions]

By employing these cost-optimization strategies, you can create beautiful custom knit sweaters that fit your budget without sacrificing quality or style. Remember, a little planning and strategic decision-making can go a long way in bringing your vision to life.

Conclusion

The world of custom knit sweaters offers endless possibilities for personalized style and branding. But with this creative freedom comes the question: how much does it cost? While there’s no one-size-fits-all answer, understanding the key factors that influence price empowers you to make informed decisions.

By keeping these factors in mind, you can approach custom knitwear projects with confidence. Remember, a little planning and collaboration with a reputable manufacturer like GUOOU FASHION can transform your vision into a beautiful, personalized sweater that stays within your budget.

Click here to learn more about GUOOU FASHION’s manufacturing capabilities.

Now that you’re armed with this knowledge, it’s time to unleash your creativity and design the custom knit sweater of your dreams!

English

English Deutsch

Deutsch Français

Français Italiano

Italiano Español

Español Русский

Русский Polski

Polski Nederlands

Nederlands Svenska

Svenska